News

Screw-In Tent Pegs Suck! - Inventor Reveals 7 ...

Screw-In Tent Pegs Suck, Here's Why... They cost more than $2 - That's all I expect to pay for a lump of steel. I love hammering in dozens of old...

Screw-In Tent Pegs Suck! - Inventor Reveals 7 ...

Screw-In Tent Pegs Suck, Here's Why... They cost more than $2 - That's all I expect to pay for a lump of steel. I love hammering in dozens of old...

Why You Need GroundGrabba: The Benefits of Anch...

GroundGrabba anchors are the perfect solution for securely and safely anchoring your festival tents and outdoor structures. Whether you are hosting a wedding, music festival, or outdoor gathering, GroundGrabba anchors...

Why You Need GroundGrabba: The Benefits of Anch...

GroundGrabba anchors are the perfect solution for securely and safely anchoring your festival tents and outdoor structures. Whether you are hosting a wedding, music festival, or outdoor gathering, GroundGrabba anchors...

Are Tent Pegs or Stakes Supposed to be Vertical...

The age old argument continues and may just continue to do so even after you read our findings. We set out to answer this question once and for all. Did...

Are Tent Pegs or Stakes Supposed to be Vertical...

The age old argument continues and may just continue to do so even after you read our findings. We set out to answer this question once and for all. Did...

Solar Farm Field Testing New Commercial Range o...

Last updated 24th May 2022 Not sure what part of Australia you live in, but we live in the Northern Rivers region of NSW. It has been raining pretty much...

Solar Farm Field Testing New Commercial Range o...

Last updated 24th May 2022 Not sure what part of Australia you live in, but we live in the Northern Rivers region of NSW. It has been raining pretty much...

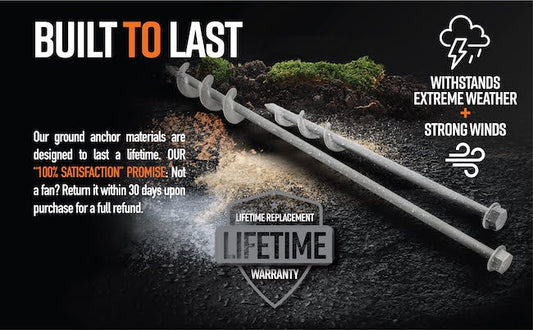

Auger Spiral Screw in Pegs

With a plethora of screw-in tent pegs or tent stakes out there, why would auger spiral screw in pegs be any better than just a screw-in tent peg like that...

Auger Spiral Screw in Pegs

With a plethora of screw-in tent pegs or tent stakes out there, why would auger spiral screw in pegs be any better than just a screw-in tent peg like that...